Extended connectivity for GEM300 automation

Extended connectivity for GEM300 automation

Agil'GEM300 is a complete .NET/C# solution for GEM300 connectivity. It handles the complexity of GEM300 automation and provides a simple interface to connect a semiconductor equipment controller application to the factory host.

GEM300 services

- Carrier and load port management

- Carrier ID verification

- Slot map verification

- Both manually and through OHT

- Process job management

- Control job management

- Substrate tracking in the equipment with substrate ID verification

- Equipment performance tracking

- Module performance management

- Collaboration between standards managed by Agil’GEM300 with minimal integrator interaction

- Include Agil'GEM

SEMI standards

The following are supported in Agil'GEM300:

- SEMI E-87 – Carrier management

- Fixed buffer

- Internal buffer

- SEMI E-40 – Processing management

- SEMI E-94 – Control job management

- Material redirection

- SEMI E-90 – Substrate tracking

- Single substrate tracking

- Batch tracking

- SEMI E-116 – Equipment performance tracking

- SEMI E-157 – Module process tracking

- SEMI E-39 – Object services

- SEMI E-30 – GEM

- SEMI E4 – SECS-I (serial protocol)

- SEMI E37.1 – HSMS-SS (ethernet protocol)

- SEMI E5 – SECS-II (message format)

Key aspects

- Agil'GEM300 ensures the use of the SEMI Standard with a .NET application as an equipment controller. This is written and published in a comprehensive C# interface.

- The Agil'GEM300 library is based on our SECS/GEM Agil'GEM library and integrates all its functionalities which is essential to manage communication between the host (MES) and the equipment controller using SEMI standards.

- High message throughput.

- Native integration between A²ECF-SEMI and Agil'GEM300 – The time and workload required to develop GEM300-compliant equipment software are significantly reduced through A²ECF-SEMI.

Benefits

- Reaching the right "time-to-market" – Customer equipment can be implemented into fabs sooner.

- Reducing software investment and focusing on their core business – The customer can adopt an existing software solution, freeing up time and resources to focus on their core activity.

- Field-proven products – The Agil'GEM library is present worldwide and is used in more than 50 fabs around the globe.

- Increasing equipment controller maintainability – Our products are constantly evolving. As they are implemented in many different fabs and configurations, they are regularly tested and updated over time.

Documentation

Agileo Automation provides its customers with extensive documentation, including a developer's guide explaining the different steps of the Agil'GEM300 integration process.

This guide is divided into three main parts:

- Environment preparation

- Project creation and library integration

- Instantiation of the GEM300 environment

- Communication

- Operational scenarios

- Introduction to carrier and job management

- Carrier management: Agil'GEM300 E87 integration guideline

- Job management: Agil'GEM300 E40 and E94 integration guidelines

- Substrate tracking: Agil'GEM300 E90 integration guideline

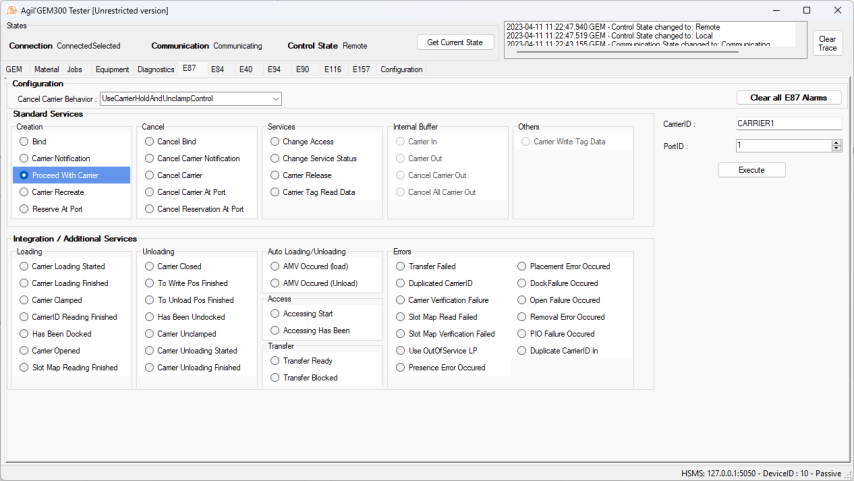

The guide also includes a presentation of the Agileo Agil'GEM300 Tester Tool which allows the user to test and observe the implementation of each functionality of the Agil'GEM300 components. It can also be connected directly to a host or a simulator such as Speech Scenario (a GEM300 test plan is provided with Speech Scenario).

Support

At Agileo Automation, we make it a priority to stand by our customers to ensure that they get a good understanding of the GEM300 standard and that its integration takes place in the best possible conditions. We not only provide our customers with a product, but also support from A to Z - our engineers are always ready to answer any question that may arise throughout the project.