03/27/2018

3R adopts the A²ECF framework on its universal testing machines

3R adopts the A²ECF framework with its universal testing machines, creating 5 times the sales and catching up on a technical software backlog of several years in the face of the competition.

Authors:

Marc ENGEL – Managing Director, Agileo Automation,

Benjamin BOVO – Head of Sales, 3R

Created in 1987, 3R is the number one manufacturer of testing machines made in France. Beginning with specific test benches, in 2004 3R created a department devoted to universal testing machines and produced a complete range of machines aimed at testing the tensile strength of materials such as metals, composite materials, plastics etc., for many markets ranging from the aeronautics, metallurgy, automobile and nuclear power industries to higher education.

Agileo Automation offers automation solutions for manufacturing equipment. Agileo is the creator of A²ECF, a software framework designed to build control applications for manufacturing machines and let them communicate with the factory IT systems.

While developing the universal testing machines department, 3R felt the need to modernize machine control software with 3 specific aims in mind: to meet the competition in terms of user-friendliness, to offer a clearer, more intuitive and more current interface and lastly to increase its efficiency through limiting the configuration time of each machine and the after-sales service needs of future customers.

Collaboration with Agileo Automation began in 2013. Agileo first assisted 3R in defining the software architecture for universal testing machines.

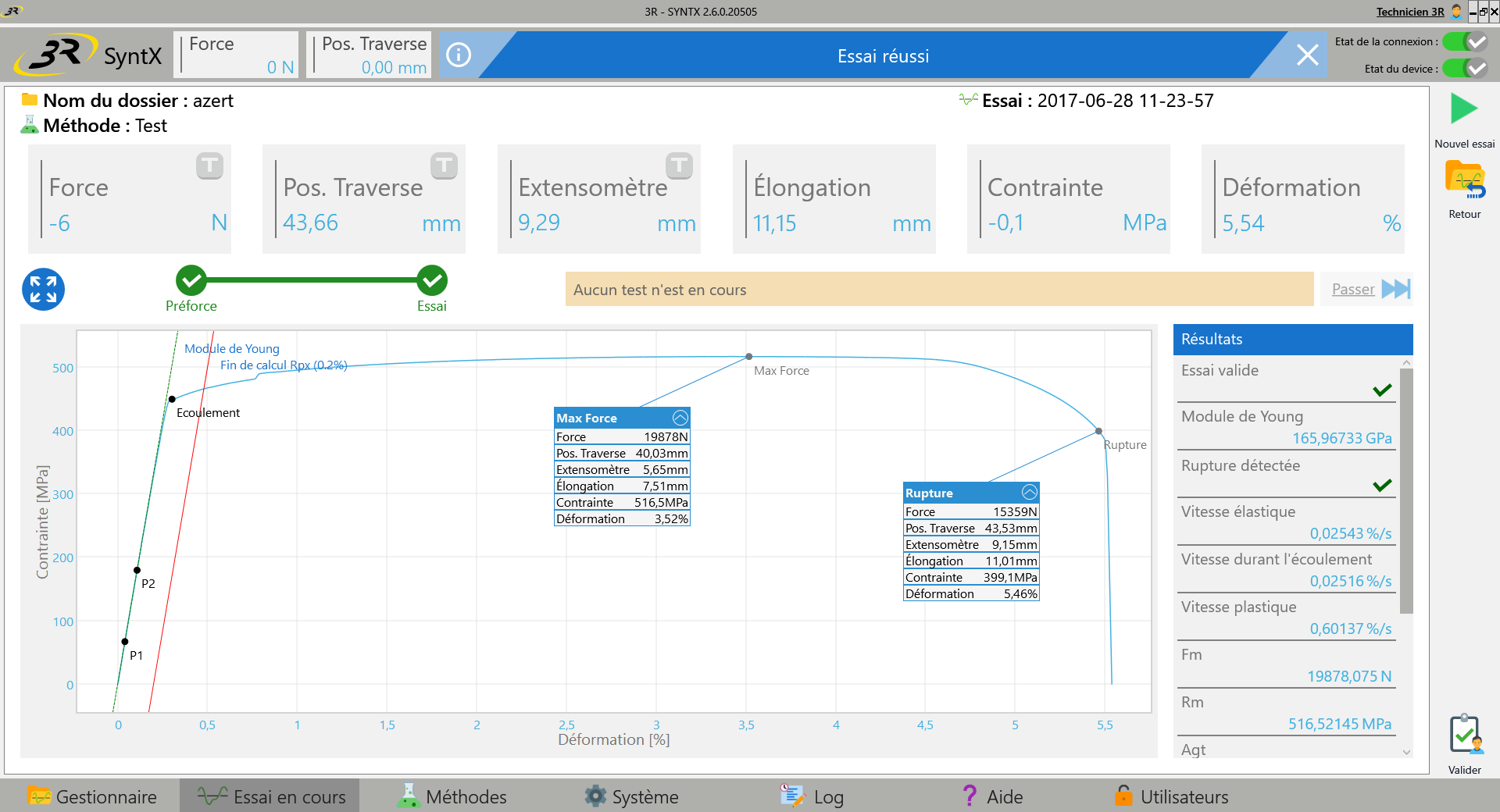

Agileo’s software team then created the SyntX software based on the A²ECF framework’s architecture to reduce the development time and make use of the components as well as an architecture that was designed for machine control.

A modeling of the tests through a language specific to the field of materials resistance was proposed.

Olivier VITTU, Head of the project at Agileo explains “We favored a flexible approach by developing complete use cases early on, to quickly obtain feedback from 3R and to be able to clarify needs in regular meetings.” Benjamin BOVO adds, “The biggest challenge was not really knowing the precise destination. We aimed in the direction of a product that was estimated to be ideal, based on a state-of-the-art analysis. As the development and implementation progressed, the target became more and more precise. Customer feedback allowed us to improve the software’s functionalities and to clearly meet customers’ expectations and those of the market. Agileo’s development method, along with its capacities, allowed us to be guided through the development process and in this way maximize our chances of success.”

Based on A²ECF customized with 3R colors, the new SyntX software was subsequently implemented on the machines. This new intuitive interface set to the latest graphics standard was an asset when it came to commercialize the machines.

Benjamin BOVO explains that “By collaborating with Agileo, we were able to turn a corner and improve the software’s quality to the level of our machines’ mechanics. Since 2013 we have multiplied our universal testing machine sales by 5, while at the same time reducing our after-sales service time by the same factor.”

A²ECF’s scalable architecture now means that 3R can broaden its service with, for example, an automated loading option for its machines, and also to plan this software solution’s implementation across the entire range of machines including those used for construction materials.

--

Videos of the tool and software accessible through the link https://www.youtube.com/watch?v=5Flfpq5QEKs